Numerical Busbar Protection Scheme

|

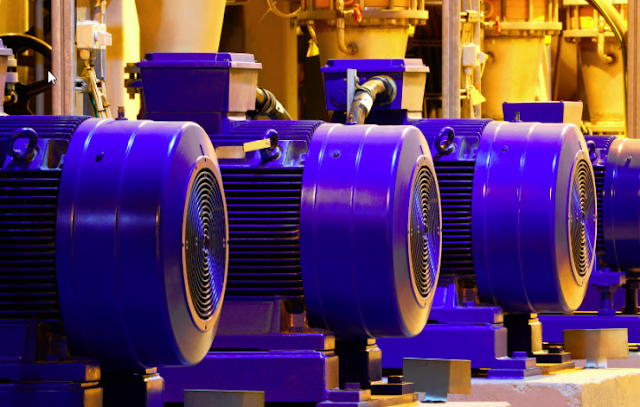

| Photo Credit: EMS Industrial |

The application of numerical relay technology to busbar protection has lagged behind that of other protection functions. Static technology is still usual for such schemes, but numerical technology is now readily available. The very latest developments in the technology are included, such as extensive use of a data bus to link the various units involved, and fault tolerance against loss of a particular link by providing multiple communications paths. The development process has been very rigorous, because the requirements for busbar protection in respect of immunity to maloperation are very high.

Related Article: Busbar Protection

Feeders each have their own processing unit, which collects together information on the state of the feeder (currents, voltages, CB and isolator status, etc.) and communicates it over high-speed fibre-optic data links to a central unit. For large substations, more than one central unit may be used, while in the case of small installations, all of the units can be co-located, leading to the appearance of a traditional centralised architecture.

For simple feeders, interface units at a bay may be used with the data transmitted to a single centrally located peripheral unit. The central unit performs the calculations required for the protection functions. Available protection functions are:

- protection

- backup overcurrent protection

- breaker failure

- dead zone protection

|

| Architecture for numerical protection scheme |

Because of the distributed topology used, synchronisation of the measurements taken by the peripheral units is of vital importance. A high stability numerically-controlled oscillator is fitted in each of the central and peripheral units, with time synchronisation between them. In the event of loss of the synchronisation signal, the high stability of the oscillator in the affected feeder unit(s) enables processing of the incoming data to continue without significant errors until synchronisation can be restored.

Related Article: Fundamentals of Generator Protection

|

| Busbar protection relay using the latest numerical technology (MiCOM P740 range) |

- Network Protection and Automation Guide | Download

.webp)

No comments: