Motor Circuit Branch Circuit Protection According to NEC 430.52

|

| Motor Control Panel |

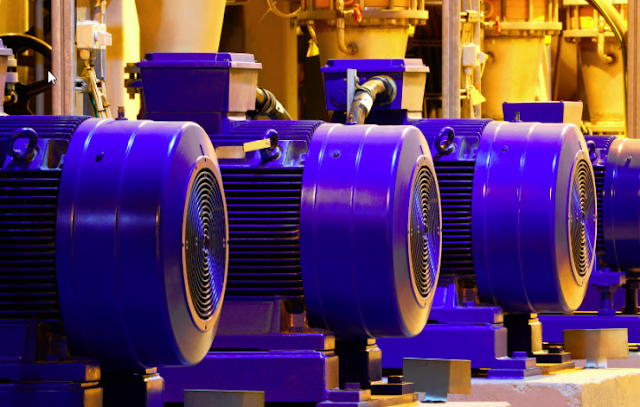

Motor circuit branch protection is an essential part of protecting motors and other equipment from damage caused by overcurrents. Overcurrent can occur due to various reasons such as short circuits, ground faults, and motor overloads.

Therefore, knowing how to compute the motor circuit branch protection is crucial for the following reasons:

- Prevents Equipment Damage - Overcurrents can cause severe damage to motors and other equipment. Therefore, proper protection through circuit breakers, fuses, or other protective devices is necessary to prevent damage.

- Increases Safety - Overcurrents can also pose a safety hazard to personnel working on the equipment. Proper protection ensures that the equipment does not pose a risk of injury to personnel.

- Increases Equipment Life - Protecting equipment from overcurrents can increase its lifespan, thereby reducing the need for frequent repairs or replacement.

- Meeting Electrical Code Requirements - Electrical codes require that motor circuit protection be provided to protect equipment and personnel from overcurrents. Failure to comply with these requirements can lead to legal and safety issues.

- Reduces Downtime - Overcurrents can cause equipment to shut down unexpectedly, resulting in costly downtime. Proper protection can prevent such shutdowns, increasing productivity and reducing costs.

There are several components that can be used to protect an electric motor from damage caused by overcurrents or other electrical faults. Here are some of the most common ones:

- Circuit Breakers - Circuit breakers are automatic switches that can interrupt an electrical circuit when they detect an overcurrent or other fault. They can be used to protect motors from overloads or short circuits.

- Fuses - Fuses are protective devices that contain a metal wire or element that melts when there is an overcurrent. Fuses can be used to protect motors from overloads or short circuits.

- Thermal Overload Relays - Thermal overload relays are protective devices that use a bimetallic strip to detect and respond to overloads. When the motor current exceeds a pre-set level, the relay will trip, disconnecting the motor from the power source.

- Surge Protectors - Surge protectors are devices that protect electrical equipment from voltage spikes or surges. They can be used to protect motors from voltage surges that can cause damage.

- Enclosures- Enclosures are protective covers that can be used to shield motors from environmental factors like dust, moisture, or debris.

Motor Circuit Protection According to NEC 430.52

Motor circuit protection describes the short-circuit protection of conductors supplying power to the motor, the motor controller, and motor control circuits/conductors. 430.52 provides the maximum sizes or settings for overcurrent devices protecting the motor branch circuit. A branch circuit is defined in Article 100 as “The circuit conductors between the final overcurrent device protecting the circuit and the outlet(s).”

Note that the branch circuit extends from the last branch circuit overcurrent device to the load. Table 430.52 lists the maximum sizes for Non-Time-Delay Fuses, Dual Element (Time-Delay) Fuses, Instantaneous Trip Circuit Breakers, and Inverse Time Circuit Breakers. Sizing is based on full load amp values shown in Table 430.247 through 430.250, not motor nameplate values. For example, the maximum time-delay fuse for a 10HP, 460 volt, 3 phase motor with a nameplate FLA of 13 amps would be based on 175% of 14 amps, not 175% of 13 amp.

Source: Cooper Bussmann

- 430.52(C)(2) reminds the user that the maximum device ratings which are shown in a manufacturer’s overload relay table must not be exceeded even if higher values are allowed by other parts of 430.52.

- 430.52(C)(3) details the requirements that instant-trip CBs can only be used if part of a listed combination motor controller.

.webp)

No comments: