Circuit Breaker Essentials

|

| Circuit Breaker | Source: Siemens |

The function of a Circuit breaker is to isolate the faulty part of the power system in case of abnormal conditions. A Circuit breaker has two contacts - a fixed contact and a moving contact. Under normal conditions, these two contacts remain in closed positions.

When the circuit breaker is required to isolate the faulty part, the moving contact moves to interrupt the circuit. On the separation of the contacts, the flow of current is interrupted, resulting in the formation of an arc between the contacts. The contacts are placed in a closed chamber containing some insulating medium (liquid or gas) which extinguishes the arc.

Arc Interruption

- High Resistance Interruption- In this method of arc interruption, its resistance is increased so as to reduce the current to a value insufficient to maintain the arc. The arc resistance can be increased by cooling, lengthening, constraining, and splitting the arc. This method is not suitable for a large current interruption.

- Current Zero Interruption- In the case of a.c supply, the current wave passes through a zero point, 100 times per second at the supply frequency of 50 Hz. This feature of arc is utilized for arc interruption. The current is not interrupted at any point other than the zero current instant, otherwise, a high transient voltage will occur across the contact gap.

Restriking voltage and Recovery Voltage

After the arc has been extinguished, the voltage across the breaker terminals does not normalize instantaneously but it oscillates and there is a transient condition. The transient voltage which appears across the breaker contacts at the instant of the arc being extinguished is known as restriking voltage. The

power frequency RMS voltage, which appears across the breaker contacts after the arc is finally

extinguished and transient oscillations die out, is called recovery voltage.

Related Article: What are the different type of circuit breakers and its uses?

Circuit Breaker Rating

Circuit breakers have the following important ratings

- Breaking Capacity

- Making Capacity

- Short-time Capacity

The breaking capacity of a circuit breaker is of two types.

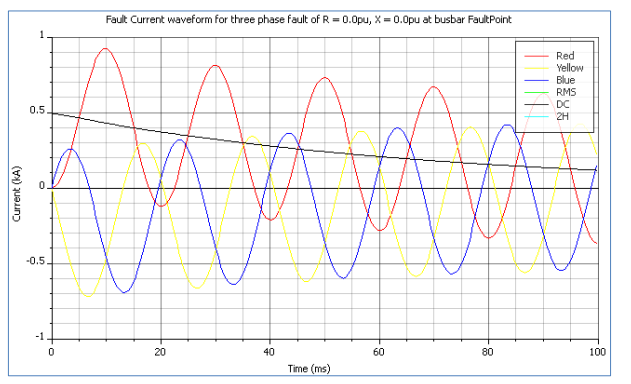

- Symmetrical breaking capacity

- Asymmetrical breaking capacity

Symmetrical breaking capacity

It is the RMS. Value of the ac component of the fault current that the circuit breaker is capable

of breaking under specified conditions of recovery voltage.

Asymmetrical breaking capacity

It is the RMS value of the total current comprising of both ac and dc components of the fault

current that the circuit breaker can break under specified conditions of recovery voltage.

Making Capacity

The rated making current is defined as the peak value of the current (including the dc component) in the first cycle at which a circuit breaker can be closed onto a short circuit. Ip in Figure. is

the making current.

Short-time Current Rating

The circuit breaker must be capable of carrying short-circuit current for a short period while

another circuit breaker (in series) is clearing the fault. The rated short-time current is the rms value

(total current, both a.c. and d.c. components) of the current that the circuit breaker can carry safely for

a specified short period.

Rated Voltage, Current and Frequency

The rated current is the rms value of the current that a circuit breaker can carry continuously

without any temperature rise in excess of its specified limit.

The rated frequency is also mentioned by the manufacturer. It is the frequency at which the circuit breaker has been designed to operate. The standard frequency is 50 Hz. If a circuit breaker is to

be used at a frequency other than its rated frequency, its effects should be taken into consideration.

Operating Mechanism

Different manufacturers adopt one of the following:

- Pneumatic

- Hydraulic

- Spring

Compressed air system for the pneumatic mechanism:

The pressure of the operating air produced by the self-enclosed motor compressor unit is

supervised by a pressure gauge and controlled by a pressure switch (located in the breaker

control cabinet).

The pressure switch has four sets of contacts each of which operates at a

different pressure levels for the following functions: Start/stop, low-pressure indication,

reclosure interlock, closing, and opening interlock.

This type of system is provided for each pole of 420 KV and 765 KV CB.

Hydraulic Mechanism:

The hydraulic cylinder is mounted at the base of the interrupter unit and the hydraulic rod is pushed up during closing stroke and pushed down during opening stroke. Moving contact and puffer cylinder are linked with the hydraulic rod.

The hydraulic oil at atmospheric pressure from the low-pressure tank is pumped into

accumulators at high pressure (310 kg/cm2

).

High-pressure oil is used for opening and closing operations.

During opening operation high-pressure oil from the lower area of the hydraulic piston is discharged

into low-pressure tank by opening the appropriate hydraulic valve.

Spring Mechanism:

For CB upto 245 KV, a spring operating mechanism is used. The closing spring gets charged by a geared motor. During closing stroke the closing spring is discharged. It closes the breaker and

also charges the opening springs.

The Circuit breaker mechanism is basically very simple since it comprises a motor-reducer and

two springs (one for closing and one for opening), plus their solenoid-operated latching

devices.

The closing spring after having been charged by the motor-reducer is kept ready for closing by it's a latching device. As soon as energized, the closing control coil friggers the closing latch thereby causing the closing spring to operate the breaker to the closed position and simultaneously charge the opening spring. From now on, the trip latch keeps the breaker in the closed position and the opening springs ready for opening.

The compact design of the mechanism avoids the need for the opening springs to be located

close to each pole and permits the opening operation to be performed by only one spring

accommodated in the control cabinet.

Reference:

Title: Handbook for Protection Engineers

Author: Mohammed Fasil

Document: PDF | pages 107- 114| Download

.webp)

We should avoid from circuit breaker and use the precautions before to solve the errors. Similarly, I am remove your ranking error through Digital Marketing Services USA and increase your business rank.

ReplyDelete