Type and Purpose of Phase Disconnects

|

| Photo Credit: Control Automation |

A disconnect switch is any solid-blade switch installed to provide a means to isolate or sectionalize a circuit. Unless a disconnect switch has a load interrupter, it has no capability to interrupt load current. Disconnect switches have no capability to open automatically under fault conditions. Disconnects are used in underground and overhead transmission and distribution systems.

Switches can be categorized according to the insulating medium surrounding the contacts. The insulating medium helps cool and extinguish arcs that may form between the contacts as they open. As stated above, disconnects are not designed to interrupt load current unless equipped with a load interrupter. However, charging current in the line can still cause arcs to form when disconnects are opened.

The four general classes of disconnects are:

- Air switches, with air as the insulating medium.

- Oil switches, with dielectric oil as the insulating medium.

- Vacuum switches, with a vacuum maintained around the contacts to serve as the insulating medium.

- Sulfur hexafluoride (SF6) switches, with SF6 gas as the insulating medium.

Disconnect switches can open very small charging currents to unload equipment, but that is all. The low current arc is broken by swinging the moving arm in a 90-degree arc, providing a long gap. Disconnect switches can be operated by motors, by an insulated lever connected to an actuating arm that moves the switchblade as many medium-voltage pole-top switches are, or manually by using a hook stick (a long insulated pole with a hook attached to one end).

Read: Protection Relays in Power System

Type of Disconnects

- Non-Load Break Disconnect Switch: A non-load break disconnect switch should be operated by using the inching method. Because the switch should not be used to drop a load, there should be no arc developing as the switch is opened slowly. If there is an unknown load and an arc starts to develop, the switch should be closed immediately. At a distribution voltage, single-phase disconnect switches are normally equipped with hooks to allow a portable load-break tool to be used to safely provide the load-break capability.

- Load-Interrupter Disconnect Switch: Disconnect switches with load-interrupters come in all voltages. They can be three-phase gang-operated switches or single-phase switches. Depending on the type, load interrupters are operated by hot stick, operating handle, or remotely by way of a low-voltage motor. A load-interrupter switch has no capability to open automatically under fault conditions. Load-interrupter switches are normally rated at 600 amperes or less.

|

| In-Phase Disconnect |

- Air-Disconnect Switch: An air-disconnect switch is not equipped with arcing horns or other load-break devices. It, therefore, cannot be opened while the current is flowing. If the disconnect switch should be opened while the current is flowing in the line, an arc would likely be drawn between the blade and its stationary contacts. The hot arc would melt part of the metal, thereby damaging the switch. The purpose of a disconnect switch is to isolate a line or a piece of equipment for the purpose of making the disconnected line or equipment dead electrically, thus making it safe for repairs, tests, or inspections.

Read: Basic Guide for Power System Protection

- Oil-Disconnect Switches: An oil switch is a high-voltage switch whose contacts are opened and closed in oil. Oil switches may be used as disconnects, circuit breakers, or reclosers. The switch is actually immersed in an oil bath, contained in a steel tank. The reason for placing high-voltage switches in oil is that the oil may help to break the circuit when the switch is opened. With high voltages, a separation of the switch contacts does not always break the current flow, because an electric arc forms between the contacts. If the contacts are opened in oil, however, the oil helps to quench the arc. Oil is an insulator and, therefore, helps to quench the arc between the contacts. The three lines of a three-phase circuit can be opened and closed by a single oil switch. If the voltage is not extremely high, the three poles of the switch are generally in the same tank. But if the voltage of the line is high, the three poles of the switch are placed in separate containers.

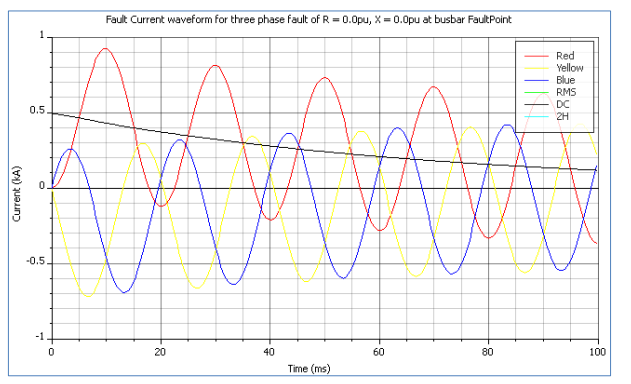

- Phase Disconnects | Download

.webp)

I am appreciative of this blog's ability to provide information on such an important subject. I discovered other segments here, and I'm excited to put these new instructions to use. Electrical Products Suppliers in UAE

ReplyDeleteThis article contains a lot of valuable info. I am amazed by the quality of the info and also it is a beneficial article for us, Thanks for share it.electrical contractor

ReplyDelete