Video: Arc Flash Accident

What is an Arc Flash?

NFPA 70E (the relevant standard from the National Fire Protection Association),

Arc Flash is a “dangerous condition associated with the release of energy caused by an electrical arc.”

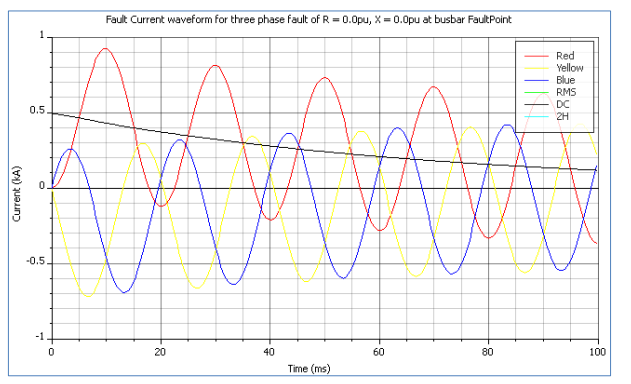

It is measured in terms of arc flash incident energy E (AFIE), which is used to determine the level of Personal Protective Equipment (PPE), and in terms of an arc flash protection boundary (FPB). Arc Flash Hazard is the term used to define the danger to people working on live parts. The Arc Flash Hazard Analysis defines the procedures which limit the damage of electrical arcs on personnel and, by measuring the released energy, defines the risk areas and determines the relevant level of the personal protective equipment (PPE). An electrical arc occurs whenever there is a loss of insulation between two conductive objects at sufficient potential (voltage).

Near high power electrical equipment, such as transformers, service entrance switchgear or generators, the short-circuit power available is high and consequently so is the energy associated with the electrical arc in case of a fault. The energy released by the arc due to a fault creates a rise in the temperature and pressure in the surrounding area. This causes mechanical and thermal stress to nearby equipment and creates the potential for serious injuries in the vicinity.

The arc formation in a cubicle can be described in 4 phases:

- Compression phase: the volume of the air where the arc develops is overheated due to the release of energy. The remaining volume of air inside the cubicle heats up from convection and radiation. Initially there are different temperatures and pressures from one zone to another;

- Expansion phase: from the first instant of internal pressure increase, a hole is formed through which the superheated air begins to escape. The pressure reaches its maximum value and starts to decrease from the release of hot air;

- Emission phase: due to continued contribution of energy by the arc, nearly all the superheated air is forced out by an almost constant overpressure;

- Thermal phase: after the expulsion of the air, the temperature inside the switchgear nears that of the electrical arc. This final phase lasts until the arc is quenched, when all the metals and the insulating materials coming into contact undergo erosion with production of gas, fumes and molten material.

Click to view video...

|

| Arc Flash Accident |

Protective Measures:

Passive measures Passive measures can be barriers or procedures:

- Arc-proof switchgear: designed to direct the arc energy to vent out the top of the switchgear, and limit the energy directed to the front;

- Remote control operation of protection and switching devices; keep personnel at a safe distance from the equipment;

- Closed door racking-in/out of the withdrawable circuit breakers.

- Remote or longer operating mechanisms so that racking-in/out operations can be carried out at a safe distance;

- Barriers between personnel and equipment during racking-in/out or opening/closing operations;

- Reduction of the short-circuit current by disconnection of unnecessary power supply sources: for example, disconnecting parallel transformers and opening bus ties;

- Remote control devices for racking-in/out of the circuit breaker at a safe distance.

Active measures

The passive measures described above might not be adequate with a high available short-circuit current; limiting the time of the energy release becomes necessary. In order to reduce the released energy, the following measures can be taken.

Circuit breakers with fast tripping times: a fast trip may clash with the selectivity requirements; typically the nearer to the supply source the circuit breaker is, the higher the trip times shall be set. Also, the higher the short-circuit power, the higher the requirement for service continuity, as in the main circuit breaker;

- Zone selectivity: this co-ordination type allows setting of a fast trip time only for the circuit breaker immediately upstream of the fault. Thus it is possible to achieve a high selective coordination while keeping a fast trip.

- Choosing ‘fast’ setting values for maintenance operations.

Source:

- ABB Circuit Breaker

- Exxon Mobile

.webp)

As you know making a youtube channel is exceptionally simple but getting endorsers and see isn't so easy so in case you're one of those clients who is not getting endorsers and sees at that point fair contact me, and we’ll give you a youtube channel as per necessity. YouTube Account for Sale

ReplyDelete